Updated Sept. 2013

In the last few years, there has been a huge increase in demand for rabbit processing services. This MPU is currently processing around 80 rabbits a week, about every other week. Producers are selling the rabbit meat at farmer’s markets, restaurants and retailers- one producer commented that he “can’t grow them fast enough.” However many rabbits he can produce, there’s a market for all of them. Previously, rabbit processing was done “under the table” as there was no legal option for rabbit producers in Kentucky. Now, with a state-approved MPU, producers can legally process and sell rabbit meat within the state.

This small mobile poultry processing unit was built in Kentucky in 2001 by Heifer International with Kentucky State University (KSU), Partners for Family Farms (PFF), and the National Center for Appropriate Technology (NCAT). State-approved but uninspected, the MPU is owned and maintained by KSU. Farmers use it on a rental basis to process poultry and aquaculture.

The training and use manual for this unit, complete with HACCP plan and detailed operating procedures, is available for a small fee. For this and other information about the unit, contact:

Steve Skelton

(502) 597-7501

steven.skelton@kysu.edu

NOTE: Call first, as email is not always accessible.

Basic information

Capacity per day: It depends on who is staffing the unit, but 200-250 is probably the limit.

Hours/day of operation: 7.5 maximum (over that, user pays overtime)

Weeks/year: It is busy almost year-round: aquaculture from January – March; poultry starts in April; in November, KSU uses it for campus farm turkeys. Some months it’s used Mon-Thurs every week.

Species: poultry (e.g. chickens, turkeys, pheasants, quail), aquaculture (e.g. caviar, paddle fish, prawns), and rabbits

Services: rented to farmers to slaughter and process these species

Square feet: The trailer is 160 sf. The docking station is 960 sf.

#/type of employees: one part-time: the MPU coordinator, an employee of Kentucky State University

Annual sales revenues: they don’t know exactly, but it breaks even: rental and training fees cover all operating costs except the coordinator, who is paid by KSU.

Price of Services: $75 for first 50 chickens, $0.75 each additional; $75 for first 15 turkeys, $3.50 each additional; $50 for the first 50 rabbits, $0.50 for each additional (cost includes gas, water, electricity, aprons, booties, cleaning). The unit how has a vacuum packaging machine- bags are $0.22 each. $75 for for the first 2 years of training, $50 after that (every user, every two years). There is a flat $75 fee to rent the unit for aquaculture processing.

Operational costs: Hard to know, because the MPU uses KSU farm infrastructure (e.g. water).

Retail on-site: no

Wholesale: no

Inspection: neither; state-approved & operating under exemption

Certified organic: no

Certification agency: n/a

Custom work: all custom

Source verification on label: n/a

Market opportunity/processing problem

Small, specialty poultry producers can raise free-range or organic poultry to boost income on limited-resource farms and feed the market for niche poultry (e.g. local, cage-free, and pasture-raised). Many would like to expand their operations but may lack access to processing, because very few small poultry processing plants that are government licensed or inspected are open to independent producers. Some states allow some number (from less than 1000 to 20,000, depending on the state) of birds to be processed on-farm without government inspection.

Kentucky, however, allows no such exemption. At the time the MPU was built, Kentucky farmers who wanted to raise specialty poultry for market had nowhere to process their birds. Since the MPU began operating, one independent poultry processing plant has opened. SS Enterprises, which is just outside of Bowling Green, is Kentucky’s first USDA inspected independent poultry processing plant.

Organizations involved

The MPU was one element of a multi-year pastured poultry project, a collaboration led by Heifer, including Kentucky State University and Partners for Family Farms (PFF; another nonprofit). Two Kentucky state agencies, the Department of Agriculture and the Cabinet of Health, were also involved extensively. Sustainable Agriculture Research and Education (SARE, within USDA) provided the seed money. University of Kentucky (Lexington) also provided guidance and support. The National Center for Appropriate Technology (USDA) developed materials to help farmers start and maintain pastured poultry businesses (see below).

Basic history/development

In the mid 1990s, Heifer and partners began working with limited resource farmers in several southern states, including Kentucky, to explore the pastured poultry model. Farmers liked the idea but had limited access to legal processing facilities. Farmers also wanted information about feed, labor, appropriate bird types, and business planning and development.

In 1997, Heifer and the above-listed partners, working with the farmers, decided to build a mobile processing unit for use in Kentucky. (Similar teams were assembled in Alabama and Mississippi to plan MPUs for their states, but their regulatory agencies were not as cooperative, and they had to find alternatives.)

With a $15,000 SARE grant as seed money, the team consulted with state and federal agencies about health and safety requirements, then designed and built the MPU. Poultry MPUs had already been built elsewhere around the country, but Heifer raised the bar, building “the Cadillac of poultry MPUs.” Partners for Family Farms, the KY Department of Agriculture, Kentucky State University, and others helped raise the $55,000 needed to do so. The MPU was completed in 2001, and it began to travel from farm to farm.

Soon, however, the MPU was immobilized: both the USDA and state agencies weren’t happy with it and required changes (detailed below in regulations section) related to waste water and having an enclosed room for slaughter, separate from the processing area. In addition, under Heifer ownership, the cost of liability insurance was prohibitively expensive. Heifer sold the MPU to KSU in 2005 for $1; KSU hired Steve Skelton to get it up and running again. A permanent, enclosed docking station was built at KSU that satisfied the regulators.

Today, the MPU is mobile again and very busy. As MPU Coordinator, Skelton is regularly on the road, taking it between the three docking stations. The docking stations are at KSU, in Frankfort; at Morehead State University, in Morehead; and in Jackson County. He also takes it to aquaculture ponds. While all poultry must be processed at a docking station, aquaculture can be processed pond-side, without a docking station.

The MPU now has ten regular users. It is considered a pioneer in mobile processing, and many producers and organizations from across the country have visited it or requested information.

As part of the larger pastured poultry project, NCAT developed farmer-friendly materials on small-scale poultry processing, business development and entrepreneurship, nutrition, genetics, and other aspects of raising and selling poultry (available at NCAT/ATTRA).

Funding sources

The MPU cost $70,000 to plan and build. SARE provided $15,000 in seed money, within a larger ($100K) grant for the larger pastured poultry project. The other $55,000 was raised by Partners for Family Farms and others. The MPU coordinator is an employee of Kentucky State University. All other operating expenses are covered by user fees.

Business plan

No business plan was written beyond “build it and they will come.” Fortunately, that turned out to be true.

Deciphering regulations and complying

At the beginning, the regulatory requirements were not at all clear, even to the agencies themselves. Heifer, with help from PFF, consulted with both federal and state agencies and then built the MPU. But once it was up & running, problems arose.

USDA originally said it wouldn’t inspect the MPU, so Heifer assumed it would operate under the federal exemption for plants processing fewer than 20,000 birds per year. But when the ribbon cutting ceremony for the MPU got USDA’s attention, the agency said no, that exemption only applies to stationary plants, not to a facility used by multiple operators at multiple locations. Heifer then had to get what they called “an exemption from the exemption,” from USDA. This only happened after the Kentucky Department of Agriculture and the Cabinet of Health Services were satisfied with how the MPU operated, which required significant modifications to the original plan.

Health Services required the waste water to be treated and not spread on farm fields. They also required an enclosed kill area that was less flimsy than the original, moveable awning. The solution that was finally approved was a docking station that met specific sanitation requirements (listed below). A farmer can use the MPU for on-farm processing if he builds an approved docking station, but it is much less expensive to travel to the existing ones.

Aquaculture processing can be done pond-side, without a docking station, as long as there is a level place to place the trailer, potable water, and electricity. Water used for processing can go back into the pond or a drainage ditch.

Today, Health Services must be informed every time the unit is used, and they are present at many processing sessions. USDA checks out the MPU once per year and reviews HACCP paperwork. All MPU users must be trained every two years on how to use the MPU, including HACCP, SOPs, and SSOPs. The first half is in the classroom, the second half is processing birds. They then take a test, and if they pass, they are given a facility manager number, which must go on all their product labels and is good for two years. Without that number, they cannot process. The MPU coordinator makes sure HACCP is followed each time the unit is used.

The MPU operates under the following plans:

- Standard Operating Procedures

- Sanitation Standard Operating Procedures

- Hazard Analysis Critical Control Points

- Good Manufacturing Practices

- Recall Plan

Today, the MPU’s operating procedures are “one of the best examples of HACCP on a small scale,” says NCAT’s Anne Fanatico. The MPU’s smooth functioning is evidence that HACCP doesn’t have to overwhelm a small processing operation.

Plant design

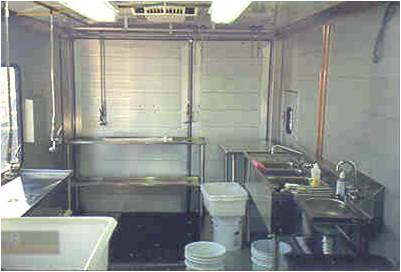

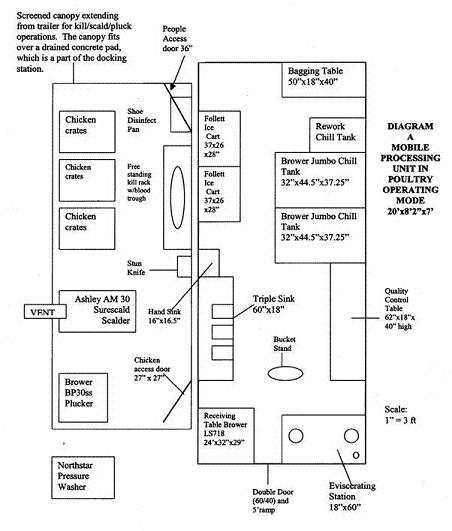

The MPU was designed by Steve Muntz, of Heifer, who consulted many people along the way. The MPU itself is an enclosed, gooseneck cargo trailer, 20’ x 8’, with the processing equipment pulled into a building shell. The trailer must be pulled by at least a ¾ ton pickup truck with a gooseneck ball and electrical connections for trailer and brake lights.

The MPU must be used within a docking station that meets these requirements:

- Level pad to park the unit;

- An additional concrete pad for the slaughter area, sloped to drain;

- Electric: 200 amp service panel that is either waterproof/covered;

- Water: from an approved municipal source or a tested well, with a flow rate of at least 10 gallons per minute;

- Wastewater treatment: 750-gallon grease trap and a 1500-gallon septic tank that has a float sensor with an alarm or light as a fill indicator; water must be pumped out and hauled to an approved wastewater treatment plant;

- MPU user must bring a 100-lb. propane tank to provide heat for the scalder (propane tanks cannot travel with MPU due to risk);

- Ability to maintain high level of sanitation and exclude insects/pests (at KSU, it is a pole barn).

How it works:

- Birds are slaughtered outside, passed through the window into the trailer to be eviscerated, cleaned, and chilled;

- Sanitation procedures require users to wear boots, aprons, gloves, hair nets, and no jewelry;

- Bird health: only birds that originate from hatcheries approved by the National Poultry Improvement Plan (NPIP) can be processed, and the MPU coordinator is trained to condemn unhealthy live birds and identify internal signs of disease;

- Users clean up after each use: wash, rinse, sanitize;

- The MPU coordinator provides oversight and assistance if needed.

Big Glitches and how they were solved

As noted above, the MPU was originally meant to be used at many sites, both farms and fairgrounds. But state agency site and docking station requirements prevented that. The MPU cannot be hooked into a municipal waste water system. Instead, it must have its own septic system, but few septic contractors are willing to come to pump out waste water. (KSU contracts with a septic company to pump it out occasionally.)

Also, Health Services insisted on an enclosed kill room, separate from the processing area. The MPU originally created this with a side-opening awning to create a screened kill area. However, the awning was hard to set up and take down, and the screen wasn’t stable in wind, so insects could get in. The area under the awning was also quite small and difficult to work in. An enclosed building, as at the KSU docking station, provides more room and is better at keeping out insects and other pests.

Insurance was also a big problem at first. Because Heifer is a nonprofit organization, it had to require all users of the MPU to have $1 million in liability insurance. This was prohibitively expensive for many farmers. Under KSU ownership, users need only sign a waiver of liability each time they process, though they are advised to carry a product liability rider on their farm policy.

For full traceability, each product label has the user name, address, telephone, and the user’s facility manager number, which the user is given after passing the biannual training course. All labels are also marked “Exempt Poultry P.L. 90-492.”

Required equipment

Outside the trailer: stun knife, cones, scalder, picker; Inside the trailer: overhead shackles to convey birds during evisceration and cleaning, stainless steel tables, buckets for offal, water hoses and spray nozzles, chill tank, ice maker (not portable), knives, scale with label printer, vacuum packer, bags, thermometers, and other supplies.

Staff needed and how they were found/trained, what they cost

The MPU is used by the farmers themselves. However, because the MPU requires a high level of knowledge to use, a KSU employee serves as coordinator.

All users must take a one-day Facility Manager training once every two years, which covers HACCP, pathogen reduction, sanitation, and standard operating procedures. KSU provides the training, which costs $50 per user.

Financial sustainability plan

Fees for service cover the operating costs except for the coordinator.

Markets accessed

Marketing is done by individual producers, who report that they consistently sell everything they can process. They sell to farmers markets, restaurants, and some even to grocery stores. One couple simply put an ad in their local paper and can barely keep up with demand; one of their customers regularly drives 72 miles to buy a dozen at a time.

Growth to date

The MPU has been running smoothly since 2005. By providing access to processing, it has allowed small, specialty poultry and aquaculture businesses in KY to expand their operations and improve their profitability.

In 2007, users processed ~4000 birds, and coordinator Skelton expected business nearly to nearly double in the coming year, with the Morehead docking station up and running and a third planned for Jackson County. As of 2011, the unit has ten regular users and thirty producers are certified to use it.

As a pioneer in small-scale and mobile poultry processing, the MPU has been a model for similar efforts around the country. No one has replicated it exactly (it was expensive and can’t be used for on-farm poultry processing), but people and organizations continue to be interested in all aspects of it, to help them design their own processing solutions and to navigate the regulations. For example, someone who went through the MPU training decided he could operate his own plant and built his own small, stationary, USDA-inspected poultry processing plant in Bowling Green, KY (SS Enterprises).

Greatest Challenges

In the beginning, the greatest challenge was developing a deeper level of trust and understanding between producers and state agencies. The project development team had to help the Kentucky Department of Health realize that farmers are not out to break any laws. They also taught producers how to document their work and helped them understand the reasoning behind certain food safety practices. Looking ahead, the biggest challenge appears to be having enough units to meet demand. The number of small growers in the state has increased and Kentucky’s buy local movement is going strong. The state went from about 50-60 farmers markets in 2005 to over 140 farmers markets in 2011.

Short video about the MPU

Click on this link and scroll down to the second clip.

Additional Mobile Slaughter Unit Information

This resource discusses problems encountered by meat processors such as food safety, environmental issues, lack of USDA-inspected facilities, consumer-driven demands, and the role of Mobile Slaughter Units in meat processing. A general process of slaughtering and meat processing using an MSU is outlined. Also, this resource explains some of the costs involved in Mobile Slaughter Units. Recommendations from MSU operators provide background information on problematic areas. Although the document was written according to regulations in Wyoming, the content is applicable nationwide as long as the particular state’s regulations are followed.

Mobile Slaughter Unit for Wyoming: Assessment of Needs and Values