Processors who make small batches of sausage for independent meat producers often use commercial, pre-blended mixes. Mixing a producer’s own specialty sausage recipe is time consuming and can be a logistical headache: processors must keep unique ingredients separated and communicate numerous different recipes to staff with individual batch calculations, increasing the chance of error. Custom recipes can also present labeling challenges.

Yet when a processor uses pre-blended mixes, all spicy Italian sausage – regardless of the farm the pork came from – tastes about the same. Custom spice mixes also tend to be less expensive than pre-blended mixes. Some processors allow farmers to provide their own pre-blended, proprietary mixes, but many small farms don’t have enough product volume to work with a spice mix co-packer or commercial kitchen.

This sausage spreadsheet, provided by Smuckers Meats, is designed for small, USDA- and state-inspected plants interested in creating their own specialty sausage recipes. The spreadsheet may also be useful for small retail shops who want to make their specialty sausages more consistent while tracking costs.

Why a Spreadsheet?

Processors who wish to make custom sausage batches need to know how to test and adjust recipes, how to cost out ingredients, and how to make the recipes easy enough for staff on the floor to follow even when mixing several recipes in quick succession. The sausage spreadsheet addresses these questions with simple formulations.

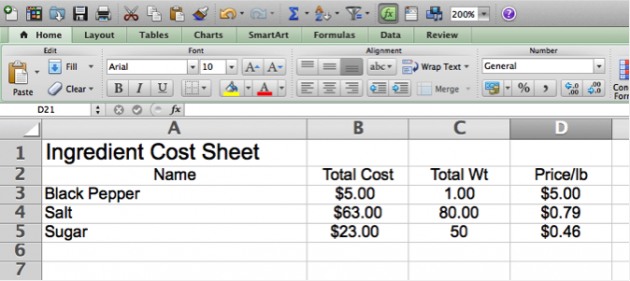

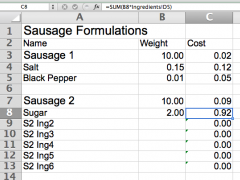

The processor initially enters the ingredients and costs for each ingredient, and then the recipe based on a standardized batch size. Once this information is entered, the spreadsheet is ready to use for specific batches: the processor enters the batch size by weight, and the spreadsheet generates a recipe with the correct ingredient measurements by weight.

Custom recipes are easy for staff to produce since the spreadsheet automatically generates the total weight of each ingredient needed for a given batch size, reducing the likelihood of miscalculation. In addition, the plant manager or sausage maker can change and adjust ingredients and ratios without the staff on the floor having to memorize or keep up with changing recipes: they simply follow the list of ingredients and weight measurements for each batch.

How to Use It

Download the template here.

Using the spreadsheet requires a basic understanding of Excel, including writing simple formulas that include cells from a linked worksheet.

First, set up the spreadsheet for your recipes:

- Type the ingredient’s name into the “name” column.

- Type the weight of that ingredient for a 10 pound batch into the “weight” column.

- Manually link the cost cell for that ingredient back to the appropriate cell in the “Ingredients” tab: when you highlight the cost cell for that ingredient in the formulation, you’ll see the formula. Adjust the formula so that it links back to the specific cost cell for that ingredient in the “Ingredients” tab.

Example 1: in the template, the formulation for Sausage 1 includes salt and black pepper. The cost cell for salt has the formula “=SUM(B4*Ingredients!D4)” because the salt’s cost is in the Ingredients tab, cell D4.

Example 2: in the images below, the first ingredient for Sausage 2 is sugar, 2 lbs per 10 lb batch of sausage. The cost cell was adjusted to read “=SUM(B8*Ingredients!D10” because the cost of sugar is in cell D10 of the Ingredients tab.

When you are ready to make a specific batch of sausage:

In the tab corresponding to the recipe you are using, enter the batch size by weight. The spreadsheet will automatically calculate how much of which ingredient to use. Print out the page, and hand it to your sausage maker.

It’s that simple.

Questions?

If you need assistance with the spreadsheet or other parts of the workbook, contact Mike Smucker at Smucker’s Meats: mike137[at]smuckersmeats.com.