This article is a sub-article of the larger article Mobile Slaughter Unit Costs and Revenues: Projections from Nevada.

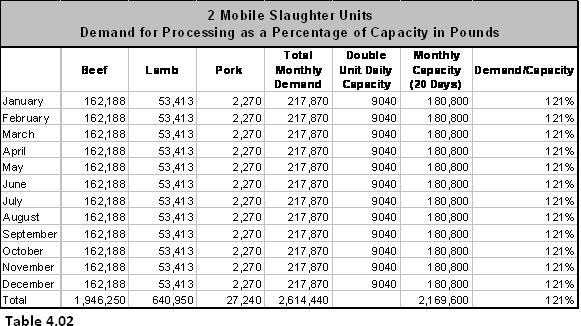

Based on research, the analysis performed, and estimated returns on investment, this study recommends operating two mobile slaughter units with a localized processing plant. This section outlines the current slaughter demand as well as the distributed slaughter schedule to maximize the use of two mobile units.

Excerpted with permission from Curtis, K. R.*, M. Cowee, A. Acosta, W. Hu, S. Lewis, T. Harris. 2007. Locally Produced Livestock Processing and Marketing Feasibility Assessment. Technical Report UCED 2006/07-13: University Center for Economic Development, Department of Resource Economics, University of Nevada, Reno.

Matching Slaughter Demand with Mobile Unit Capacity

Based on the results of the producer survey (section 2 of the full report), most livestock calving in Nevada occurs in the spring. Animals are slaughtered between the ages of 18 and 22 months, creating the majority of the slaughter demand in the fall.

Survey respondents expressed their willingness to adjust their calving schedule to regulate excess demand in the fall and allow for year round operation of mobile units. Additionally, variable pricing may be used to encourage winter and spring slaughter demand.

Existing Slaughter Demand vs. Mobile Unit Capacity

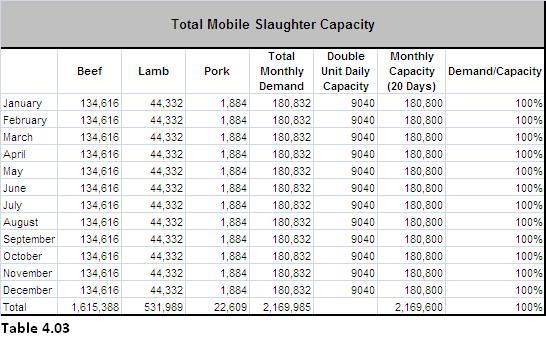

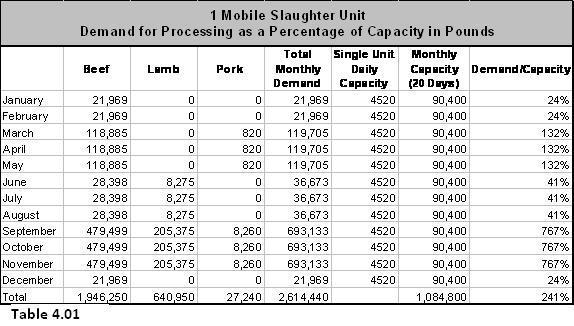

When operating at 100% of capacity and aging meat at a processing plant rather than in the mobile unit, the yearly slaughter demand exceeds capacity by 241% if utilizing a single unit. Use of two mobile units is critical to meet slaughter demand, as well as being able to cover the wide geographical area of interest. Under this scenario, demand only exceeds capacity by 121%. A third mobile slaughter unit or stationary slaughter facility will be required for growth as business expands.

Table 4.01 depicts the existing slaughter schedule by month in pounds from the survey data. As shown by the Demand/Capacity column, slaughter demand is greater than the capacity for any single mobile slaughter unit.

Distributed Slaughter Demand vs. Mobile Unit Capacity

Table 4.02 depicts the slaughter schedule by month in pounds using a distributed method to balance out slaughter demand versus the mobile units’ capacity, again based on survey results depicting the potential for flexibility with the slaughtering schedule.

Based on an average month of 20 work days, two mobile slaughter units are capable of processing 9040 pounds of meat a day, or approximately 180,800 pounds of meat per month. This assessment assumes a total of 240 operating days for each unit per calendar year.

As shown by the Demand/Capacity column, demand still exceeds capacity by 21%. To alleviate the immediate necessity to purchase three mobile slaughter units, it is recommended that two mobile slaughter units are purchased, and that overall slaughter demand is reduced (by users) by 17%, to match the capacity of those units, as detailed in Table 4.03. This results in 100% capacity utilization of the two mobile slaughter units.