These companies have designed and built MSUs, from bare bones rigs to complete, fully-equipped systems. Inclusion in this list does not imply endorsement.

www.mobileslaughter.com

Mobile slaughter unit pioneer and NMPAN Advisory Board member Bruce Dunlop shares photos, specifications, and equipment needs for mobile units.

Friesla

Friesla, located in Everson, Washington, builds both modular and mobile slaughter, cut & wrap units, and cooler/freezer units. They also occasionally sell used equipment on their site. They help walk you through the whole design process, as well as help you apply for a grant of inspection,

The Friesla mission is to help farmers and ranchers take back control of your local meat processing — on your terms, time, and at your site. Their vision is to create a global network of strong, sustainable ecosystems in which independent farmers raise, process, and deliver premium meat direct to our local communities.

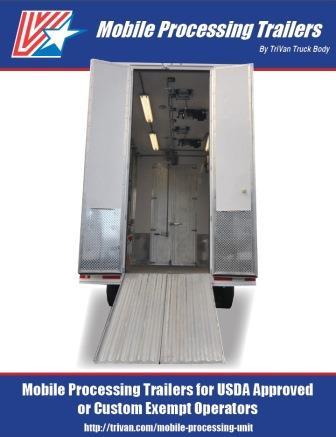

TriVan

TriVan Truck Body is located in Ferndale, Washington. TriVan has a reputation for high quality work, long-term reliability, and customer service. They also build the meat harvest units for Friesla.

TriVan Truck Body is located in Ferndale, Washington. TriVan has a reputation for high quality work, long-term reliability, and customer service. They also build the meat harvest units for Friesla.

A TriVan mobile slaughter unit comes fully equipped and satisfies USDA inspection and licensing requirements. The unit consists of a mechanical and storage area, slaughter area, and refrigeration area. Miscellaneous equipment includes knives, saws, scales and other necessary supplies. A semi truck tractor is necessary to pull the trailer and must be purchased separately, either new or used. The approximate vehicle weight is 25,000 pounds.

It takes approximately 14 – 20 weeks to receive a mobile slaughter unit. The purchase terms are 50 percent down at the time of the order, with the balance on completion.

Download 2-page TriVan MSU brochure.

Featherlite

A Featherlite mobile slaughter unit also comes fully equipped and ready to go, or it can come less equipped if the customer wishes to put in his/her own equipment.

It takes approximately 8 to 12 weeks, from time of order, for the unit to be completed.

Cornerstone Farm Ventures

Cornerstone has equipped two units so far, both for poultry. One is in Vermont, the other on Martha’s Vineyard, MA. The Vermont unit’s trailer was built by Brothers Body and Equipment, in Crestline, Ohio. View the blueprints for that mobile poultry processing unit here, provided by the Vermont Agency of Agriculture.

Plant in a Box

Plant in a Box are modular poultry processing units, being used for exempt poultry processing as well as inspected poultry processing. As of 2020, PIB are also being modified for red meat species. For just under $100K, a poultry farmer can purchase a unit and equipment. Transport, electrical, water, HACCP consulting, etc. are extra.

The Plant in a Box is designed for processors in the 10,000 to 500,000 chickens per year range. Designed for anywhere from three to six workers at 40 birds per person per hour.

Mobile Processing Trailers & Supply

Custom built beef, pork, poultry units for both slaughter and processing. Manufactured in Colorado. USDA compliant or custom-exempt options. According to their website- “Each mobile unit is custom built according to the customer’s needs. We can either provide a bare bones unit or ones with all the equipment and supplies needed to begin operations immediately. Capacity requirements may require more than one trailer.”